|

|

cofire

Back to COMBUSTION RESEARCH AND CONTROL

EXPERIMENTAL STUDY OF CO-FIRING A WOOD BIOMASS WITH PROPANE

The general objective of this

experimental study is to develop a stable, effective and controllable

process of co-firing a fossil fuel (propane, natural gas) with

renewable (wet wood biomass), providing control of a burnout of the

wood char and volatiles, as well as control of the flame dynamics,

processes of the heat/mass transfer and the formation of polluting

emissions by co-firing a fossil fuel with renewable one.

Experimental set-up

|

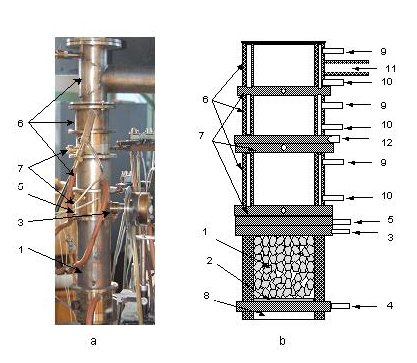

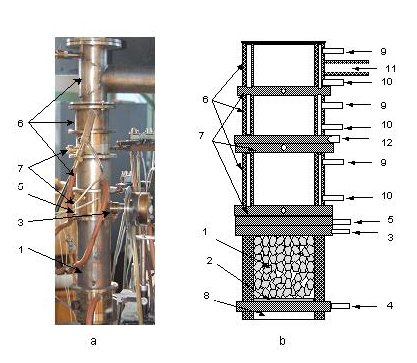

Fig.1. The digital image (a) and

schematic view (b) of the experimental set-up:

1- gasifier, charged by the wood granules, 2- steel grid, 3- swirling

propane/air burner, 4- air supply, 5- secondary air supply, 6-

water-cooled channel, 7- peepholes for the diagnostic tools, 8- ash

pan, 9- cooling water inlets, 10- cooling water outlets, 11-

measurements of the flame composition using the gas analyzer TESTO

-350XL, 12- peepholes for the radiation measurements.

|

Laboratory study of co-firing

renewable (wood granules) with fossil fuel (propane) is carried out

using a compact design (Fig.1), which includes a laboratory-scale

premixed propane/air burner (3), a wood biomass gasifier (1), charged

with wood granules and a water-cooled channel (6), downstream of which

the dominant combustion of the volatiles is developing. Combustion

conditions in the system are varied by varying the mass flow rate of

the primary air (4) into the bottom part of the combustor and the mass

flow rate of secondary tangential air flow (5), introduced from the two

tangential air nozzles of inner diameter D=5mm. The primary airflow

ignites the volatiles and initiates combustion, while the secondary

airflow completes the fuel combustion. Between the co-combustor and

water-cooled channel sections and so between the channel sections the

diagnostic sections (7) with peepholes are located to provide the local

injection of the diagnostic tools (Pt/Pt-Rh thermocouples, Pito tube,

gas sampling probe) into the flame of volatiles and so providing the

local measurements of the flame temperature, velocity and composition.

The residual ash is removed from the bottom part of the combustor (8).

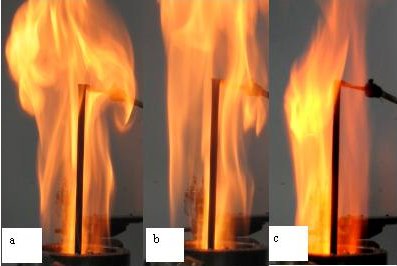

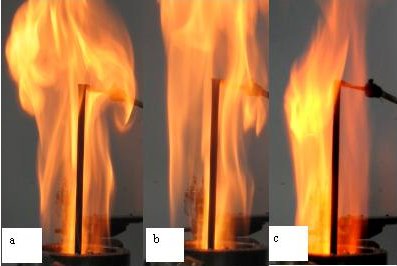

The electric control of co-firing the wood granules with propane is

carried out using the central electrode, axially inserted downstream

the flame of volatiles. The bias voltage of the central electrode in

this study could be varied within a range from –3kV to +3kV, while the

ion current is limited to 1 mA, producing the evident variations of the

flame shape (Fig.2), provoked by the field-enhanced variations in a

rate of unsteady heating and volatilisation of wood granules and

burnout of volatiles and wood char.

|

Figure 2: The electric field

effect on the shape of the free flame of volatiles: a- U=+3kV, b-U=0,

c-U=-3kV

|

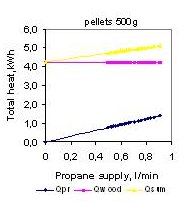

Basic characteristics of the fuel

mixture compounds:

|

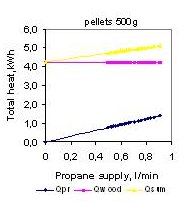

- The mass flow rates of primary and secondary airflows could

be varied in a range of 20-90 l/min.

- The rate of stoichiometric propane supply - could be varied

in a range from 0,5 to 0,85 l/min.

- The heat rate released from the propane combustion - from

770 to 1400 J/s.

- The additional energy supply from the propane combustion

can be

varied from 10% up to 25% of the net amount of the total heat released

during the burnout of wood pellets and volatiles.

- The total heat output during the burnout of wood pellets

with propane can be varied in a range from 4 up to 5kWh.

|

Diagnostic tools:

- The measurements of the radial and axial temperature

distributions in the flame are carried out using thermocouples

(Pt/Pt-Rh 10%) and the computerized date processing system with

PC-20TR;

- The measurements of the flame velocity field – by using the Pitot

tube monitors and LDV;

- The efficiency of heat production is

estimated from the calorimetric measurements in the water-cooled

sections of the experimental channel with computerized data

processing, using PC-20TR;

- The local variations of the temperature, combustion efficiency

and composition of the products (O2, CO2, CO, NO2, NO, NOx, H2) are

registered by using the gas analyzer Testo 350 XL.

- The local composition of the flame is controlled by using the

spectrophotometer SPECORD that provides the measurements of the flame

composition in the infrared spectrum range (2–15μm)

Main publications:

- M. Zake, I. Barmina, A. Desnickijs, Control of pollutant

emissions by co-firing the renewable with fossil fuel, CHISA-2006-17th

International Congress of Chemical and Process Engineering, Praha,

August 2006, CD-ROM with full teksts, P5.95, p. 1-15.

- M. Zake, I. Barmina, A. Meijere, Electric Control of Combustion

and Formation of Polluting Emissions by Co-Firing the Renewable with

Fossil Fuel, Magentohydrodynamics, 2005, N3, pp. 255-271.

- M. Zake, I. Barmina, A. Meijere, The Formation of Polluting

Emissions by the Wood Biomass Co-Firing with Propane, LFTZ, 2005, N1,

pp. 33-42.

Back to COMBUSTION RESEARCH AND CONTROL

|