|

|

Swirling flame

Back to COMBUSTION RESEARCH AND CONTROL

EXPERIMENTAL STUDY OF THE FUEL COMBUSTION AND SWIRLING FLAME DYNAMICS

UNDER THE PREMIXED AND NON-PREMIXED COMBUSTION CONDITIONS

The general objective of the research is development and

optimization of

the swirling combustion by providing the control of the swirling flame

flow formation and recirculation of products inside the swirling flame

flow and so providing control of the mixing rates of the axial fuel flow

with the swirling airflow, formation of the temperature field downstream

of the swirling flame flow, as well as control of the formation of

polluting emissions. The electric field effect on the swirling flame

dynamics is used to provide the control of the swirling flame dynamics and

the formation of the polluting emissions. It is established that the

electric force largely (F=qE) affects the axial velocity component of the

swirling flame flow with a direct influence on the recirculation and

swirling flame flow formation by varying the visible flame shape and

length, depending on the field strength and configuration (Fig.1).

|

Fig.1. The electric field effect

on the swirling flame shape and length by varying the bias voltage and

polarity of the electrode. 1. U=0; 2. U=+0.3 kV; 3.

U=+1.8 kV; 4. U=-1.8 kV.

|

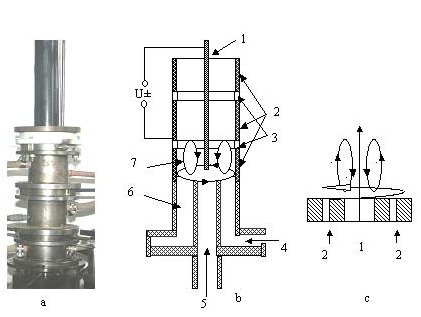

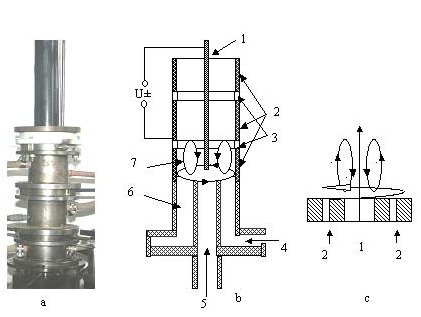

The

experimental set-up is presented in Fig.2. The experimental

apparatus consists of a gas burner, sectioned water-cooled channel and

central wire electrode. The fuel is injected axially into the burner

through a single-hole nozzle of 20mm inner diameter, while the airflow

- tangentially, through the annular duct using the air swirler with 8

peepholes of 3mm inner diameter. The swirled airflow is supplied

through the radially displaced annular duct up to the burner outlet and

then gradually mixes with the coaxial fuel flow, providing the axial

symmetry of the velocity field. The rate of air injection into the

burner can be varied ranging within 10- 20 l/min, while the propane

rate - from 0.4 to 1 l/min, providing the variation of axial flow rate

in a range of 0,6-1,26 m/s and the variation of the tangential flow

rate in a range of 3,5-7 m/s at nearly constant and relatively high

swirl number of the swirling flow at the burner outlet-

SŌēł5,6. The

equivalence rate of the air supply in these experiments can be varied

from ╬▒=0.7 to ╬▒=1.44.

The electric field to the swirling flame flow is applied in a space

between the axially inserted electrode, surface of the burner and

water-cooled channel walls. The bias voltage and polarity of the

axially arranged central electrode in the recent investigations are

varied in the range from ŌĆō3.0 kV up to +3.0 kV, while the ion current

in the flame in this study is limited to 200 mkA.

|

Fig.2. Digital image of the

experimental set-up (a), schematic of the experimental facility (b): 1-

axially arranged central electrode, 2- water-cooled sections of the

channel, 3- peepholes for the diagnostic tools, 4- tangential air

entry, 5-axial propane entry, 6-swirling burner, 7- recirculation zone;

and schematic of the flow field formation (c).

|

The investigations of the electric

field effect on the premixed propane/air flame flow include:

- The experimental study of the electric field effect on the

processes of heat and mass transfer;

- The experimental study of the electric field effect on the local

flame composition;

- The experimental study of the electric field effect on the local

temperature and rate of fuel combustion;

- The experimental study of the electric field effect on the levels

of greenhouse emissions (CO2, NOx);

- The experimental study of the electric field effect on the soot

formation, carbon capture and sequestration from the flame flow;

- The experimental study of the electric field effect on

pre-combustion fuel decarbonisation.

Main publications:

- I. Barmina, A. Desnickis, A. Meijere, M. Zake, Active

Electric Control of Emissions From the Swirling Combustion, In: ōAdvanced

Combustion and Aerothermal Technologies: The Biomass and Alternative

Fuels, Ed. Nick Syred, WB/Nato Publishing Unit, P.O.Box 17,3300 AA

Dordrecht, The Netherlands, Springer, 2007, pp. 405-412.

- M. Za─Ęe, I. Barmina, D. Turlajs, M. Lub─üne, A. Kr┼½mi┼åa.

Swirling Flame. Part 2. Electric Field Effect on the Soot Formation and

Greenhouse Emissions. Magnetohydrodynamics, 2004, Vol. 40, No 2,

p.183-202.

- M. Za─Ęe, I. Barmina, M. Lub─üne. Swirling flame. Part 1.

Experimental Study of the Effect of Stage Combustion on Soot Formation and

Carbon Sequestration from the Nonpremixed Swirling Flame.

Magnetohydrodynamics, 2004, Vol. 40, No 2, p.161-181.

Back to COMBUSTION RESEARCH AND CONTROL

|